180 sheet metal bend Manufacturers typically consider using mold bending as a processing method for structural parts that have an annual capacity of more . See more Buy White Metal File Cabinets at Staples and get Free next-day delivery when you spend $35+.

0 · sheet metal bending standards

1 · sheet metal bending specifications

2 · sheet metal bending size chart

3 · sheet metal bending machine

4 · sheet metal bending height

5 · sheet metal bending directions

6 · sheet metal bending angle

7 · 180 degree bending sheet metal

ODM precision aluminum 7075 cnc milling machined mounting parts. Material: Aluminum; Surface treatment: Sandblasted + anodizing; Note: Not all certifying agents offer online lookup, and some have a lag time for posting new certificates.Use the power of Alibaba.com, one of the largest B2B marketplaces in the world to find the right wholesale 7075 aluminum cnc milling parts for the materials and designs you are working with. These cnc machining shops can handle all requirements including milling, grinding, drilling, cutting and .

sheet metal bending standards

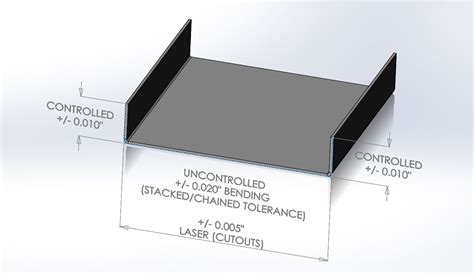

Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that . See more

Air Bending Air bending is a versatile and widely adopted technique in sheet metal fabrication. The process involves positioning the workpiece on a die with a V-shaped opening, . See more

ISO Standards Sheet metal bending operations must adhere to specific international standards to ensure quality, safety, and consistency. The International Organization for Standardization (ISO) develops and maintains these regulations. For sheet metal . See morePress Brake Press brakes are versatile sheet metal bending machines that offer high precision and repeatability in producing complex shapes. They utilize a punch and die . See more

Manufacturers typically consider using mold bending as a processing method for structural parts that have an annual capacity of more . See more In this blog post, we’ll dive into the fascinating world of bend allowance – a crucial concept in sheet metal fabrication. As an experienced mechanical engineer, I’ll share my insights and explain how bend allowance . For sheet metal bending large arcs, when the fillet R divided by the sheet metal thickness is equal to 6.5 times, the neutral layer is at the center of the sheet metal thickness. . Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet .

sheet metal bending specifications

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. Use our Bending Calculator to input material specs & get the bend allowance & deduction for your part. Watch our Bending Calculator video to see how it's done!

Hemming is the technique of joining metal sheets by bending them, often to a 180° bend. Hemming is used to making automotive body panels and pieces such as doors, hoods, tailgates, deck lids, and trunk lids. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis. This versatile technique can produce a wide range of profiles, including V-shapes, U-shapes, and more complex configurations, enabling the fabrication of various components for industries such .

In this blog post, we’ll dive into the fascinating world of bend allowance – a crucial concept in sheet metal fabrication. As an experienced mechanical engineer, I’ll share my insights and explain how bend allowance enables designers to create accurate flat .

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. For sheet metal bending large arcs, when the fillet R divided by the sheet metal thickness is equal to 6.5 times, the neutral layer is at the center of the sheet metal thickness. . and the setting angle of the bending machine is: 180-5.63=174.37 degrees. The number of bending knives above is calculated according to the empirical value. If you . Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

Use our Bending Calculator to input material specs & get the bend allowance & deduction for your part. Watch our Bending Calculator video to see how it's done!Hemming is the technique of joining metal sheets by bending them, often to a 180° bend. Hemming is used to making automotive body panels and pieces such as doors, hoods, tailgates, deck lids, and trunk lids.

sheet metal bending size chart

sheet metal bending machine

acrylic letter cnc cutting machine supplier

This Latching Box conveniently fits under the bed and is the perfect storage solution for storing linens, towels, clothing and more. The recessed lids allow same size storage boxes to stack neatly on top of each other to use vertical storage space efficiently.

180 sheet metal bend|180 degree bending sheet metal